ARMOLOY COMPANY OF PHILADELPHIA SINCE 1969

Armoloy Coating, Armoloy TDC Chromium Coating for Superior Metal Protection, Friction, Wear and Corrosion Resistant Solutions, Wear Resistant Coating, Armoloy of Philadelphia

Protect your investment with Armoloy TDC (thin dense chromium) coating for wear and corrosion resistance.

Use Armoloy for friction, purchase tough wear resistant protection and corrosion resistance.

Armoloy Coating Technology

ARMOLOY technology is unlike any other conventional chromium coating. Our proprietary process and coating conforms to existing metal surfaces with amazing detail, creating a hard, slippery and corrosive resistant surface.

Armoloy Wear Resistant Coating

What is ARMOLOY Thin Dense Chromium Coating?

ARMOLOY is a low-temperature, multi-state metal finishing process based on chrome plating technology.

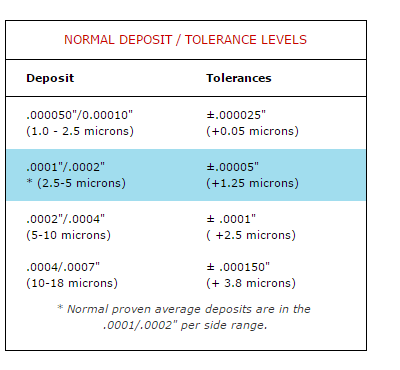

Unlike conventional chrome plating processes, ARMOLOY utilizes proprietary chemical solutions and application processes that are carefully monitored to produce its TDC (thin dense chromium) coating which follows the exact contours of the base metal with controlled deposit thicknesses.

Tough Wear Resistant Protection

HRC 78 SURFACE HARDNESS

Vickers Diamond measurements produce a 1360 – 1400 hardness rating

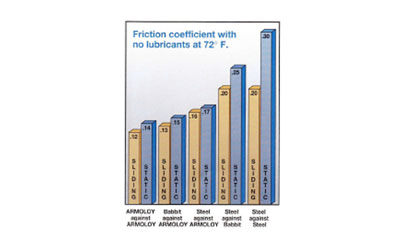

Low Friction Coefficient

ARMOLOY is a low friction coating due to its unique finish. The low coefficient of friction is invaluable especially in situations where extreme temperatures are involved.

No Hydrogen Embrittlement

ARMOLOY prevents the hydrogen embrittlement phenomenon from occuring (original conditions may, not necessarily, be removed).

ARMOLOY will not significantly affect the tensile, yield or fatique properties of the base metal. Pre/Post baking available upon request or specification.

ARMOLOY Takes the Heat

Withstands temperatures of -400°F to 1600°F.

At elevated temperatures above 1200°F it will react with carbon monoxide, sulfur vapor and phosphorous. A bright red heat oxidation occurs in steam or alcali hydroxide atmospheres. Hardness and wear resistance will be reduced, to some degree, at temperatures above 1400°F.

Resists Corrosion

ARMOLOY resists attacks by most organic and inorganic compounds with the exception of sulfuric and hydrochloric acids.

Of, course base metal porosity, surface finish and other imperfections affect basic corrosion-resistant properties.

All base metals with the ARMOLOY coating are enhanced.

Conforms to ASTM-B117 and others.

Low Friction Coefficient

ARMOLOY is a low friction coating due to its unique finish. The low coefficient of friction is invaluable especially in situations where extreme temperatures are involved.

Uniform Deposits for Precision Coating

Armoloy Technology

Armoloy technology has refined a process where its 99% pure chromium coating permeates the microscopic surface of metal surfaces creating 100% bonding characteristics that will not allow chipping, flaking or separation from the base metal.

Armoloy – Safety First

With Armoloy’s strength also comes safety.

FDA/USDA approved for use without concern on food processing equipment and pharmaceutical applications. It has passed numerous skin irritation and toxicological tests (NAMSA).

Creating Technology Solutions to Enhance Your Product’s Value

The ARMOLOY Corporate Laboratory

Through research and development we continue to enhance our technology, develop new coatings and expand ARMOLOY applications.

The ARMOLOY Shield: Five Points of Promise

- The highest quality chromium coating in the industry.

- The most effective performance from any chromium product.

- A competitive price and overall cost savings.

- Consistent, unmatched, on-time delivery.

- Personalized consulting service and continuing education.

Tough Wear Resistant Protection

- No hydrogen embrittlement

- Armoloy takes the heat

- Resists Corrosion

- Use Armoloy for friction, wear and corrosion resistance

Armoloy Company of Philadelphia

Pay your invoices via PAYPAL!

Armoloy accepts credit card payments through PAYPAL.